Abstract

According to the suggestions and opinions of experts at the 2020 implementation plan review meeting and the 2021 annual summarizing meeting, the projects will jointly address key engineering technologies, construct and debug domestic lasers, complete the global debugging of the CLAPA-I automatic target EPICS control system, and reach 1Hz. The repeating frequency objective is going well, and the project as a whole is advancing without incident.

Ⅰ. Overall progress of the project

Established and enhanced the project's internal management techniques; The personnel lists of two groups and one committee were modified.

Ⅱ. The subject advancement

In collaboration with THALES, the task group I accomplished factory acceptance of the front-end of the 2PW, 200TW laser system and reached laser power in the range of 10J." The task group I accomplished the design and delivery of the compression cavity processing for the 200TW and 2PW dual output laser system. Accomplished the building and debugging of the pump group quality tracking system, the pump source online monitoring system, and the acoustic-optical modulator system to improve the laser spectral band. The home laser system's final amplifier stage w-2 stage amplifier of the home laser system was constructed, and the first J-magnitude laser amplification was achieved.

Fig 1. Domestic laser system J magnitude light out of the scene photo

Work group II completes the approval of vacuum chamber engineering drawings and acceptance of the needed machined materials for the cavity, as well as the orderly mechanical progression of the cavity. A repetition frequency targeting system for array targets has been developed and accepted, with a target capacity of 576 rounds and steady operation at 1Hz repetition frequency. Stable performance. Complete the pre-development of the heavy frequency liquid crystal target system, which can be scraped into a nanoscale liquid crystal sheet. A miniature ion spectrometer was fabricated using Heerbek magnets.

Fig 2. Field acceptance diagram of array target repetition frequency system (left) and field acceptance diagram of cavity material (right)

Task group III optimizes the physical parameters of the horizontal beam line of the beam transmission line, identifies the magnet parameters of the beam transmission system, and completes the scheme design and public bidding of the room temperature magnet and superconducting solenoid. Additionally, the task group III has completed the scheme design of the magnet power system, EMC design, cable wiring, and bridge design. Completion of the design of the cavity BPM probe, simulation of the cavity, and mechanical design of the cavity will be followed by mechanical processing. The development of the cavity BPM electronics system is now in progress, and the design and fabrication of the ionization chamber prototype have been finished. Offline testing will commence shortly. The mechanical design work for the diaphragm slit has been finished, and arrangements have been made for the manufacturer to do mechanical processing and acquire more devices.

Fig 3. Quadrupole magnet 3D model (left) and superconducting solenoid model (right).

Fig 4. Cavity BPM probe with reference chamber (left) and cavity BPM probe internal structure (right).

Task group IV contacted accelerator control specialists from domestic research institutions to organize and conduct an online assessment of the control system intermediate layer design plan. The experts agreed that the design scheme for the control system's middle layer was extensive and comprehensive, that the job breakdown was appropriate, and that the technical path was possible; thus, the design scheme passed the expert review. Completed the hardware research and selection, bidding, and contract signing for the radiation dose monitoring system; completed the hardware selection, bidding, and contract signing for the network system; inspected the construction site of the central control room and network room in Huairou; and prepared for the installation of the safety interlock system. Upon completion of the overall testing of the CLAPA-I automated targeting EPICS control system, the system was activated under experimental light striking conditions to validate the functional integrity and system availability of the CLAPA-I EPICS system. The CLAPA-II control system simulation software and hardware environment based on the control cloud platform were developed, laying the groundwork for the next autonomous CLAPA-II control system to go online.

Fig 5. CLAPA-I EPICS control system and Phoebus control interface

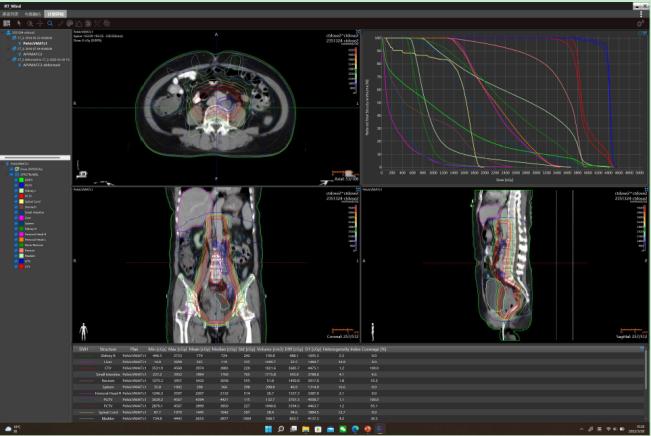

The development of software for 3D colloidal dosimetry has been launched by task group V. The software has been modularized in C++ to facilitate nesting with TPS; the basic functional modules of the planned system (DICOM interface, outlining, automatic outlining, image alignment, and fusion, dose display, and overlay) have been customized; and communications with a third party (IBA) for the purchase of quality control equipment have been finalized.

Fig 6. Functional module diagram of the treatment planning system

Ⅲ. On-site progress in Huairou

Taking into consideration the most recent engineering construction nodes supplied by the primary contractor, the major portion of the infrastructure is anticipated to be completed by the end of May. In April, the project will conduct a final site inspection to detect any potential omissions in the Huairou site works. Currently, equipment manufacturers such as gas circuits and water cooling have begun entering the site, and installation and commissioning are anticipated to be finished on April 20.